Weaving

In the product area Weaving, Groz-Beckert will among others present the quick and universal knotting machine KnotMaster AS/3. An advantage of the high-performance knotting machine is its service and maintenance friendliness.

Touch screen control is designed to make operation easy. With four tying methods, single knots, automatic repetition, doubles detector and yarn break detector the AS/3 is one of the bestsellers among the standard versions. In addition, the knotting machine is capable of handling a large variety of different yarns like cotton, wool, synthetic as well as blended and elastic yarns.

Felting

In the product area Felting, special needle solutions for different applications in the nonwovens industry will occupy centre stage. As the individual needle types of the Groz-Beckert range of products vary in terms of barb size and shape, as well as working part gauge and cross-section, the company offers the correct needle for various applications.

To obtain a high surface quality, the company recommends to use GEBECON and EcoStar felting needles. GEBECON is characterized by an increased stability combined with a high bending resistance and ensures a good surface structure in the pre-needling process. In the intermediate and finish needling, the EcoStar needle is said to guarantee a high surface quality of the end product.

The Twisted needle is designed for products where a high tensile strength is required. Its twisted working part is said to make for a particularly efficient needling. For the mechanical web bonding, among others used in the production of items for the hygiene and medical sector, Groz-Beckert offers jet strips, including HyTec Standard, HyTec D and HyTec GEBEDUR.

Knitting

The product area Knitting will put the emphasis on the interaction of needles and system parts. Transparent knitting and warp knitting machines aim to give the visitor unique insights into the interplay of all components.

The CircularKnit exhibit, a circular knitting machine replica made of acrylic glass, will visualize 14 different knitting technologies from gauge E10 to E50. The transparent WarpKnit exhibit will present the warp knitting modules that are new in the Groz-Beckert portfolio.

A special highlight from the product range is the further developed litespeed version litespeed plus. Its optimized needle geometry is designed to reduce the machine temperature and lead to significant energy savings in the knitting process. “The acrylic model litespeed plus will show the needle ‘live in action’ in an extraordinary way,” the company reports.

Carding

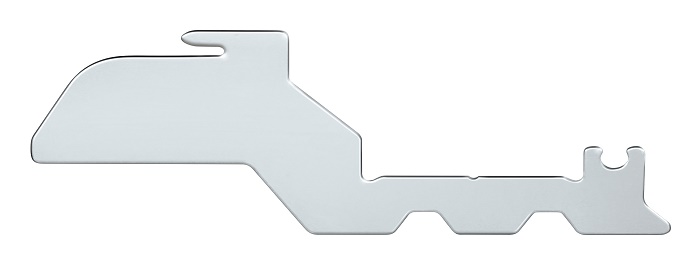

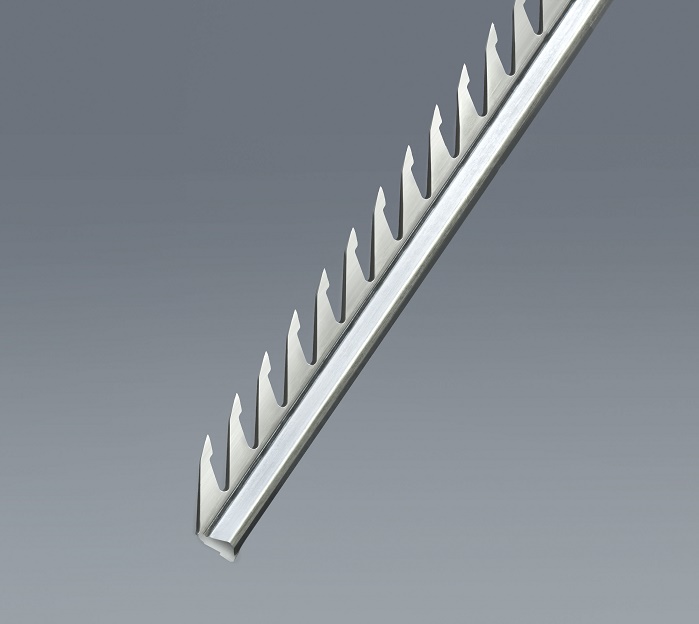

The product area Carding will highlight SiroLock, as well as EvoStep doffer and worker wires at the ITM. Together they are said to guarantee a homogeneous fibre distribution and minimized fibre consumption in the nonwovens process.

SiroLock and EvoStep wires feature a pronounced step undercut on the tooth front and a distinctive tooth shape. The optimized geometries of these wires are said to allow an up to 30 % higher fibre take-up and retention. This, according to the company, significantly improves the fibre control and prevents fibre fly in spite of high production speeds.

For the spinning industry, the product area Carding will also showcase a special doffer wire for synthetic fibres with a rib of 0.70 mm and 520 PPSI for the processing of microfibres. In addition to that, Carding will exhibit revolving tops, stationary flats, and cleaning fillets.

Source: www.innovationintextiles.com