Teijin Limited has developed a new masterbatch flame retardant that combines Teijin’s phosphorus flame retardant FCX-210 with a polymer for use on fibre, as well as resin.

This granular type is said to enable textile manufacturers to impart superior heat resistance to a wide range of products without the need to construct a dedicated facility or to add traditional flame retardants to raw materials in advance.

FCX-210

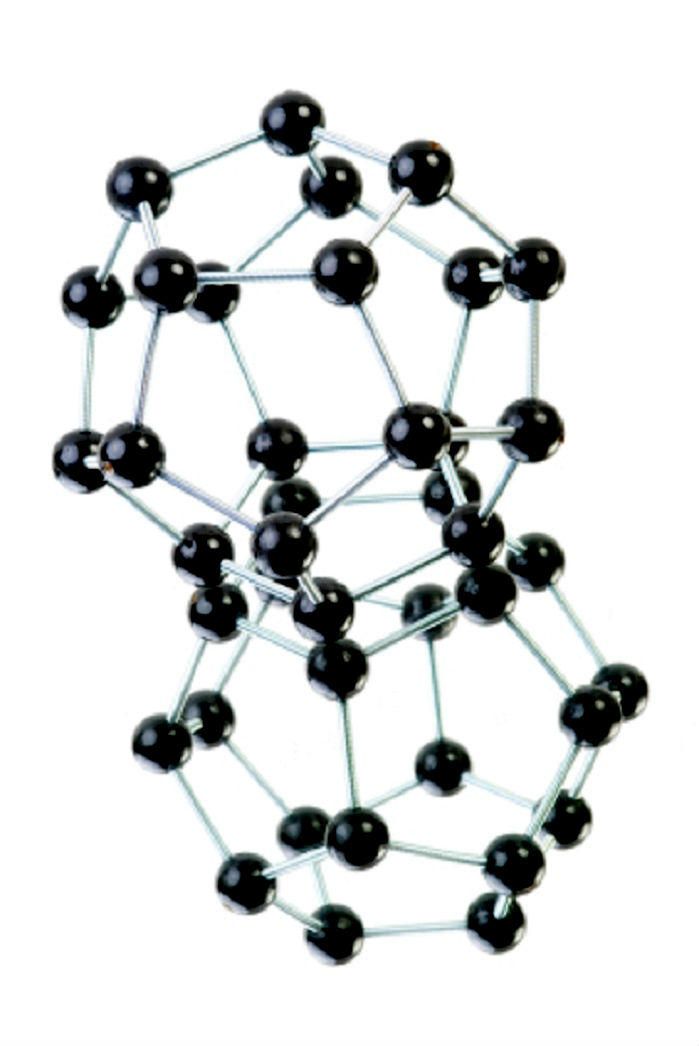

Launched in 2013, FCX-210 lends high flame retardancy to a broad range of plastics without losing any of its flame resistance or changing the original characteristics of the plastic, the company reports. Additionally, only a relatively small amount is said to be necessary.

OEM production began in Taiwan in 2014, and FCX-210 has since been widely adopted for electronics and automobiles parts. Additionally, FCX-210 is a halogen-free product, making it safer for end-users and more environmentally friendly.

New masterbatch

The new masterbatch FCX-210 is said to bring those same strengths to textile manufacturing, as well as high transparency for greater colourability. Moreover, unlike traditional phosphorus flame retardants, FCX-210 is insoluble, that realizes easier draining process, according to the manufacturer.

Teijin has begun supplying samples to expand applications for FCX-210 into interior products, such as curtains, carpets and wallpapers, which require high heat resistance. Teijin expects revenue from FCX-210 to reach US 21.9 million by 2020.

Teijin Group

Teijin is a technology-driven group offering advanced solutions in the areas of sustainable transportation, information and electronics, safety and protection, environment and energy, and healthcare.

Its main fields of operation are high-performance fibres, such as aramid, carbon fibres and composites, healthcare, films, resin and plastic processing, polyester fibres, products converting and IT. The group has some 150 companies and around 16,000 employees spread out over 20 countries worldwide.