Outlast Technologies, a leader in phase change materials (PCM), has presented its new innovations and various applications of intelligent textiles at OTWorld, the International Trade Show and World Congress, which took place from 3-6 May 2016 in Leipzig.

The company’s phase change materials can now be found in numerous everyday products, including apparel, underwear, socks, shoes, bedding, as well as some recent products in orthopaedic devices. Outlast products aim to provide an optimum climate, where unpleasant temperature changes are balanced and sweating can be reduced significantly – this is said to be done proactively before the onset of sweat.

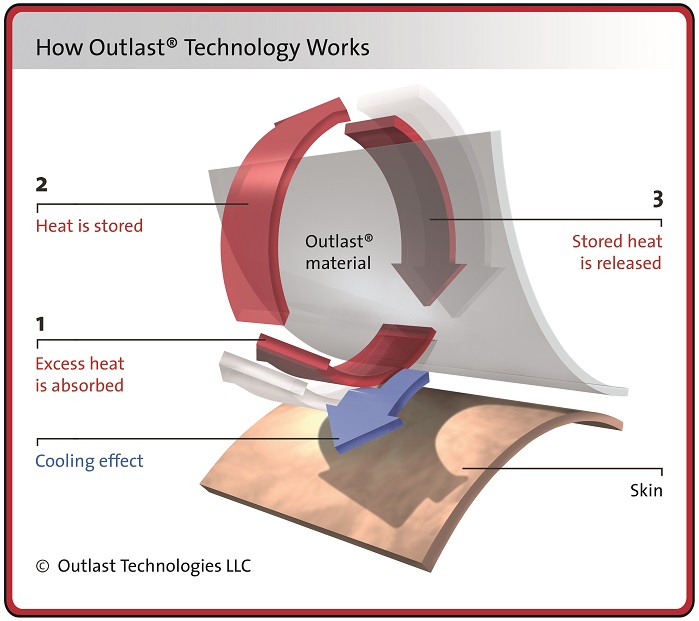

The PCM technology Outlast was originally developed for NASA to protect astronauts against the extreme temperature changes in space. Outlast technology utilizes phase change materials (PCM) that proactively absorb heat, store it and release it for optimal thermal comfort.

Alpha SmartTemp Liner with Outlast

Some manufacturers are already utilizing the smart Outlast material. The Ohio Willow Wood Company uses Outlast PCM in prosthetic liners to reduce sweating dramatically. Until now, all prosthetic liners have acted as insulators, holding heat from the residual limb within the liner and causing the amputee to sweat. The Alpha SmartTemp Liner blends silicone with Outlast heat management technology, enabling the liner to absorb and store heat to prevent the long-standing issue of perspiration in prostheses.

Outlast technology in the Alpha SmartTemp Liner is proactive, meaning that it continuously reacts to the user’s skin temperature to help mitigate the onset of sweating, the company reports. This differs from reactive solutions, such as wicking, which require the user to sweat and become uncomfortable before the technology kicks in.

WillowWood performed clinical testing on the Alpha SmartTemp Liner. During this testing, several amputee patients reported they could wear the liner 14 to 20 hours without having to remove it. While each user’s activity level, environment and personal metabolism contribute to the liner’s performance, all amputees who wore the Alpha SmartTemp Liner reportedly received noticeable benefits from the Outlast technology.

Other orthotic products

Other orthotic products (for shoulder, hand, hand wrist, knee, lower legs) made by Otto Bock, are also designed to provide a comfortable microclimate due to less sweat production.

Outlast foam cushions inside of ankle orthoses made by the French company Thuasne are said to offer an optimum climate. The German company Hydas Fabrik für Medizinalbedarf, Frankfurt, uses Outlast fibres in different bandages and supporting belts for extended heat management. In addition, compression bandages by another Germany based Bort, promise exceptional comfort due to Outlast PCM.

Proactive climate regulation

The PCMs have the capacity to absorb, store and release excess heat. This is designed to give any product containing Outlast technology the ability to continually regulate the skin’s microclimate. As the skin gets hot, the heat is absorbed, and as it cools, that heat is released.

Outlast technology is not wicking technology, which manages moisture by reacting to your sweat and pulling it away from the skin. Instead, it will proactively manage heat while controlling the production of moisture before it begins, according to the company.

Temperature fluctuation

According to the manufacturer, the microclimate on the skin is what is being targeted by the PCM. The human body temperature is 36.6°C on average. The inner temperature (e.g. heart, kidneys…) is the core temperature and ranges between small limitations, normally it is 37°C. The shell temperature of the skin and limbs as a rule is lower and varies between 28°C and 33°C.

If the normal temperature between 36.5°C and 37.4°C differs slightly at the top, we are talking of fever, if it sinks below it leads to hypothermia. If this range can be positively influenced by dynamically working Outlast materials it is possible to maintain the personal comfort zone and to reduce annoying peeks of being too warm or too cold.

Source: www.innovationintextiles.com